If you can measure it...we can make it

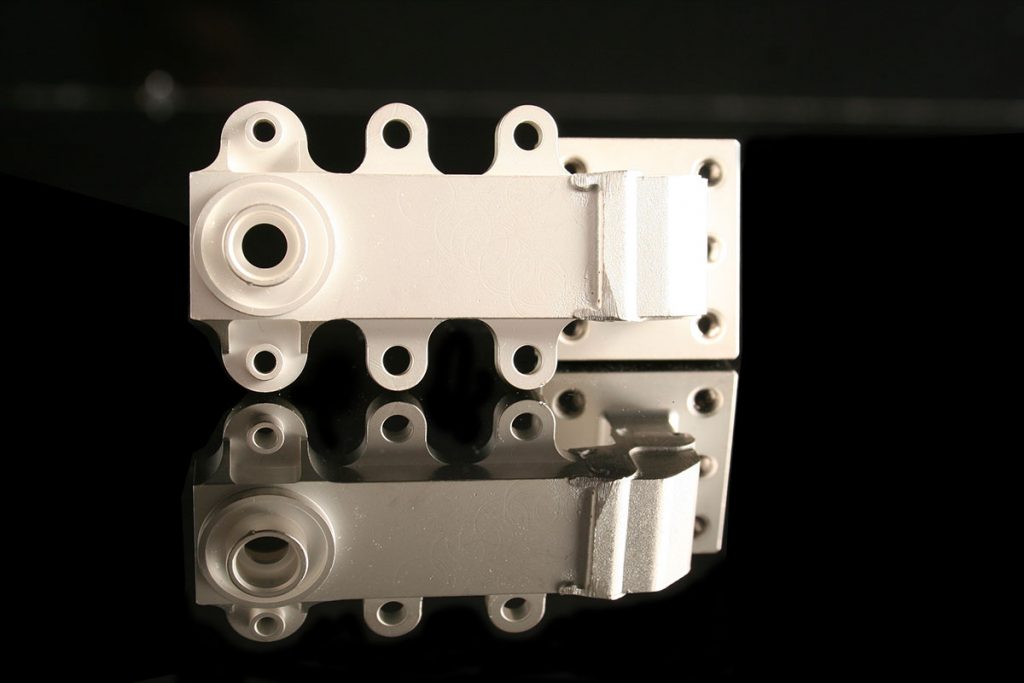

Custom aerospace parts built to your exact requirements.

About Us

Since 1996, Aerotech Engineering has built a reputation for quality, efficiency, and reliability in precision machining. With over two decades of experience, a state-of-the-art facility in Southern California, and a culture rooted in continuous improvement, we deliver complex, high-tolerance parts across a range of industries. Our customers trust our proven capabilities and our dedication to evolving with their needs—ensuring satisfaction through every phase of manufacturing.

Capabilities

This text briefly introduces visitors to your main services.

Precision CNC Machining

Our state-of-the-art CNC technology enable us to work in a wide range of materials, including high temperature alloys, titanium, stainless steels and aluminum, and to specialize in parts requiring extremely tight tolerances.

CNC Turning Centers

Our CNC turning equipment gives us the ability to manufacture components with extremely tight tolerances.

CNC Machining Centers

Our CNC milling machines have the capability for four- and five-axis machining. They also feature pallet-changers allowing for dedicated setups, minimizing changeover and maximizing productivity.

Assembly

We have the capability to produce a wide variety of sub-assemblies that require heading, stamping, flaring, press work, riveting and installation of Heli-Coil® inserts.

Deburring

We have a wide range of deburring capabilities including high-energy vibratory tumbling, grit blasting, buffing and polishing.

Prototyping

Our prototype shop enables us to produce small-quantity production lots using our CNC turning and milling equipment.

Quality

Quality Planning Methods

At Aerotech Engineering, quality is embedded from the start—through meticulous planning, precise engineering, and rigorous inspection at every stage from quote to shipment. This integrated approach is what sets us apart in the precision manufacturing industry.

Manufacturing Engineering

Our engineering philosophy is rooted in continuous process improvement, always seeking better and more efficient ways to manufacture. By combining real-world experience with advanced CAD/CAM software, our engineers design processes that meet customer specifications and ensure technical feasibility.

Quality Planning

Quality planning begins the moment a purchase order is received, with a thorough review of every step in the manufacturing process to ensure all requirements are met before production begins. This proactive approach ensures each order is completed to the highest standards.

Inspection

Our team of fully trained and qualified inspectors use the latest equipment to insure the product is fully certified and traceable per Customer requirements, including records of manufacturing, special processes and raw materials.

Certifications

Aerotech Engineering is certified to ISO 9001 and AS 9100, the premium standard for the aerospace industry. We are also a certified supplier to Fortune 500 companies and OEMs.

Gage Control

We maintain a vast inventory of gages to support high-precision, tight-tolerance machining across a wide range of part configurations. Our in-house calibration equipment meets ANSI/NCSL Z540 standards, ensuring accuracy and compliance at every step.

© Aerotech Engineering, Inc.